Alignment & Balancing

"In my 40 years of experience, I’ve seen countless reliability programs chase complex solutions to complex problems while ignoring the fundamentals. What I’ve learned is this: your machines aren’t that complicated.

If they could talk, they’d tell you, “Friction, Lubrication, Alignment, and Balance—fix these first!”

...it’s where every asset reliability journey should begin"

Ian Ware

Alignment & Balancing instruments may look similar, but there is a difference!

Acoem was a pioneer in the development of the world’s first shaft alignment tool with visible red laser and integrated software that calculated measurement values, the use of touchscreens with icons and graphics for industrial instruments in the mid-1990s and introduced wireless sensors in the mid-2000s. Trusted for over 40 years, they continue to lead the industry today.

The Path to Alignment Success

Shaft alignment is a cornerstone of reliable machinery operation and crucial to protecting the operational efficiency and life expectancy of your rotating machinery.

It also reduces stress on your equipment and helps avoid unexpected failures which may cause full process shutdowns or safety incidents.

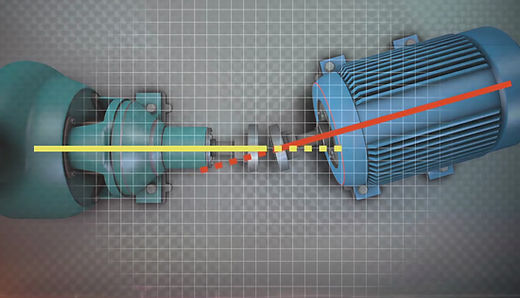

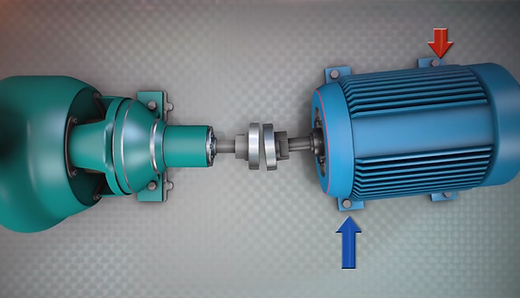

Motors face three main types of misalignments: angular misalignment, offset/parallel misalignment, and combination misalignment—when a motor shaft experiences both types of misalignment at the same time.

In the case of pumps, misalignment causes higher energy consumption and their parts experience greater wear and tear, which means more frequent maintenance and higher cost. Bearings, seals, and shafts all wear down more quickly when your motors and pumps are misaligned.

Misalignment also causes excessive vibration, which if left unchecked, can go on to damage other components, leading to extended downtime.

Even the smallest angle misalignment can reduce the lifespan of your components by 50% with studies revealing that large industrial and manufacturing facilities lose (on average) 323 production hours annually due to unplanned downtime and a major contributor cited was improper machinery alignment.

Fixing shaft alignment issues is one of the simplest ways to extend the life of your equipment and save your business both time and money.

With Acoem task-oriented laser shaft alignment tools, you can be confident that your machinery will be aligned quickly, easily and accurately every time, with all the guidance you need available via your tablet or smartphone.

.png)

_edited.jpg)

.png)

Four decades of excellence in alignment

What began as a mechanical workshop in Sweden in 1984, evolved to become an international leader in laser-based shaft alignment for rotating assets. Acoem developed the world’s first shaft alignment tool with integrated software that calculated measurement values with visible red laser and additional functionality, such as measurement of straightness, perpendicularity and parallelism.

We were pioneers in the use of touchscreens with icons and graphics for industrial instruments in the mid-1990s and introduced wireless sensors in the mid-2000s. We have continued to design and manufacture cutting-edge, user-centric alignment solutions that require minimal set-up time and utilise application software that empowers mechanics and maintenance teams. We remain committed to focusing on digitalisation, ease of use and accessibility for our customers worldwide.

The Acoem AT-400 is a cutting-edge alignment solution designed to provide robust precision for machinery alignment. With dual-axis sensor technology, the AT-400 ensures accurate alignment for compressors, blowers, fans, turbines, pumps, gearboxes, and more.

Featuring a long measurement distance of up to 20 meters and a high-resolution point laser detection system (0.001 mm), this system is perfect for those seeking unmatched reliability and ease of use in critical maintenance tasks. Cloud connectivity streamlines report sharing, while the lifetime warranty underscores its reliability.

Ultrasonic ultrasound condition monitoring, Predictive maintenance equipment, Ultrasonic ultrasound leak detection Australia, Handheld ultrasonic ultrasound instruments, Online monitoring systems for plants, Airborne, ultrasound ultrasonic inspection, Bearing fault detection tools, automatic bearing lubrication, Steam trap testing equipment, Ultrasonic maintenance technology, Industrial asset monitoring systems, Powering Predictive Maintenance with Ultrasonic Precision, problem-solving, reduce downtime, precision diagnostics, bolt stress measurement, bolt strain measurement, bolt elongation measurement, 30+ Years in industrial reliability, Local expertise in QLD, SA, VIC & WA, Authorised UE Systems distributor, Industry-trusted products and training, Technical support and on-site consulting, predictive maintenance, life cycle monitoring, vibration analysis, vibration monitoring, Manufacturing, Mining, Oil & Gas, Food Processing, Subsea, power Utilities, water utilities, Inspecting Heat Exchangers, Boilers, Condensers, Determining CFM loss, calculating energy savings, recording and reporting survey results, Electrical Inspection, Safety Considerations, Overview of Types of Electrical Equipment, Voltages Defined Acoustic Effects Versus Heat Generated Defects, Integration of Ultrasound and Infrared Methods

Detection Methods for High Voltage Equipment, Overview of Equipment for High Voltage Inspection, Detection Methods, Confirmation Methods, Substation Inspection, Radio Frequency Interference, Television Frequency Interference, Detection Methods for Low Voltage Inspection: Techniques, Contact Approach, Mechanical Inspection, Valves, Compressor Inspection, Hydraulic Valves, Steam Trap Inspection, Steam Applications, Steam Trap types, Acoustic properties, Inspection Techniques, Recording and reporting, Mechanical Inspection, Considerations of Ultrasonic Generation, Strategies of Mechanical Inspection, Review of Proactive and Predictive Maintenance Concepts, Troubleshooting Methods Overview, Trending Methods Overview, Inspection of Compressors, Gears, Pumps, Motors & Fans, Isolating Sound Sources

Bearing Inspection, Trending Concepts, Condition-Based Lubrication, Lubrication Starvation, Over-Lubrication, Levels of Failure, Monitoring, Data Logging and Sound Recording methods, Connecting to Recording Devices, Vibration Meters and Computers

Sound Spectral Analysis, Recording and Reporting Results

DMS Software Overview and Route Generation, Airborne Ultrasound Technology, Applications and Methods, Airborne Ultrasound Inspection, Supervisors, Energy Auditors, Service Company personnel who perform PDM, energy audits, leak detection, ultrasonic predictive maintenance in australia

Shaft alignment tools to boost the productivity & longevity of your critical rotating machinery

Precision laser shaft alignment tools make the process of measuring and correcting misalignment of your machinery easier, more accurate and repeatable.

With the right technology, novices and experts alike can make informed decisions and operate machinery with greater efficiency, minimising wear, production stoppages and unnecessary costs.

Shaft Alignment Accessories

Simple, easy operation with advanced features and capabilities, including geometric measurements. The ultimate in shaft alignment tools.

Not sure which system best suits your needs?

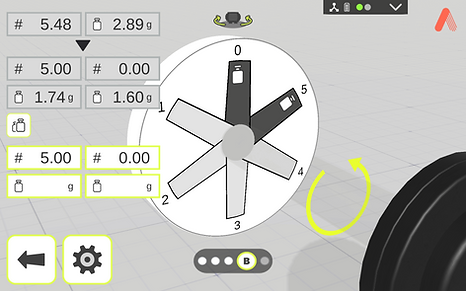

Having pioneered wireless technology in condition monitoring, Acoem is now revitalising the field of machine balancing that has seen little to no innovation for far too long. They continue to forge ahead with groundbreaking tools like the Falcon wireless data collector and the Eagle wireless diagnostic tool, a legacy now advanced even further by the Acoem Wireless Balancer. This industry-first solution enables single and dual-plane balancing of rotating machinery with rigid rotors, enhancing both safety and efficiency. Engineered for precision, the Wireless Balancer provides real-time diagnostics, eliminating the complexity and hazards of traditional wired systems.

Maximum Safety and Flexibility

No more cables – move freely and work more safely around machinery

Distant Access

Perform balancing operations from a safety distance up to 20 meters

Unmatched Precision and Speed

Multi-sensor synchronisation: Simultaneous measurement in 6 directions

Fast Learning Curve

Removing human errors from the process

Complete field visualisation

360° machine rotation to avoid errors

Guide U™

3D Graphical guidance at all steps of the process

Intelligent Correction

Smart balancing assistant

All-in-One Ecosystem

Integrates seamlessly with Acoem’s shaft alignment apps, Bearing Defender, Machine Defender, and NEST Vision.